PRODUCTION

Miras Textile

The entire production process from weaving to dyeing is completed within our organization.

DETECTION

The desired weight and colors are decided.

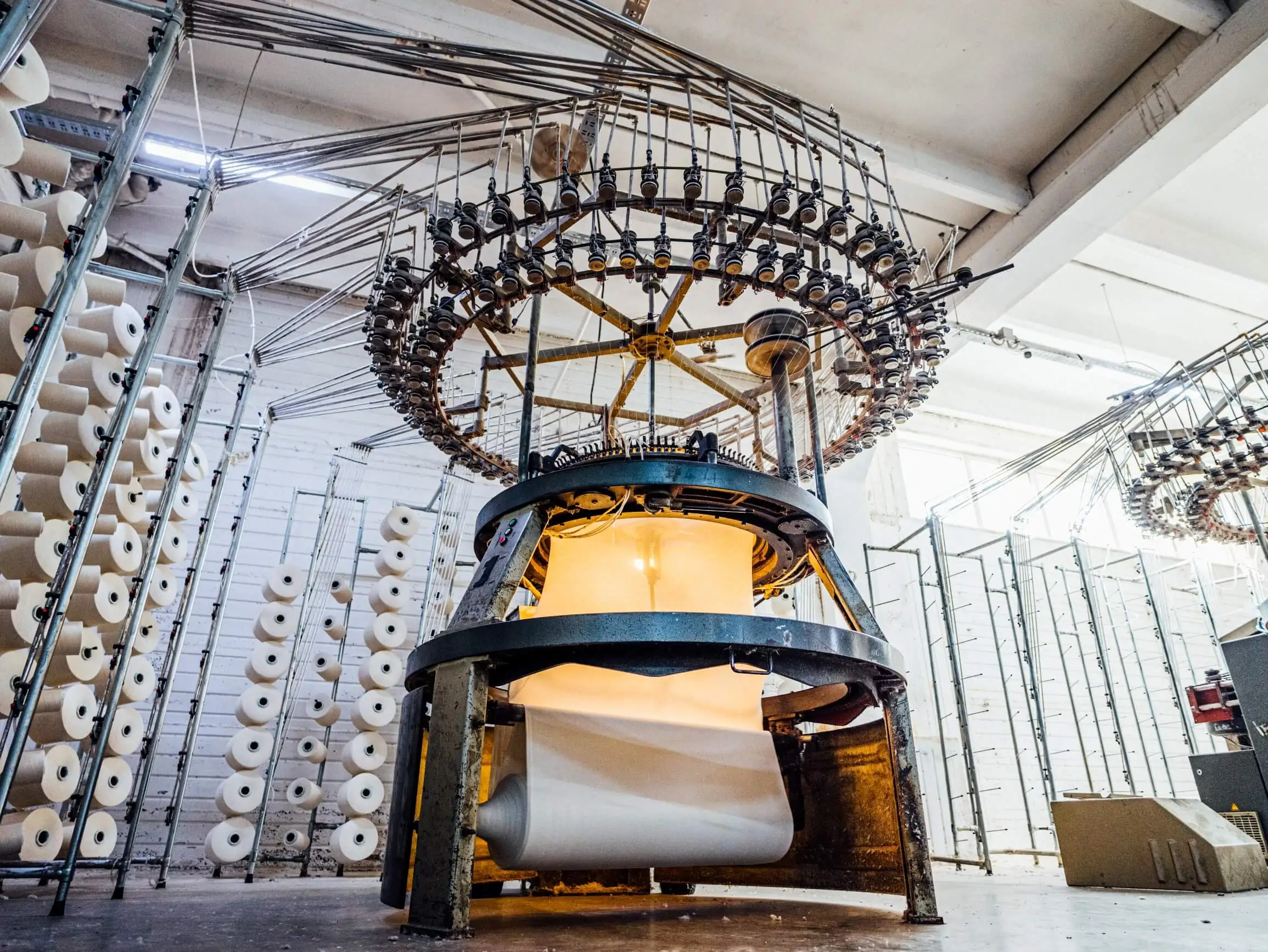

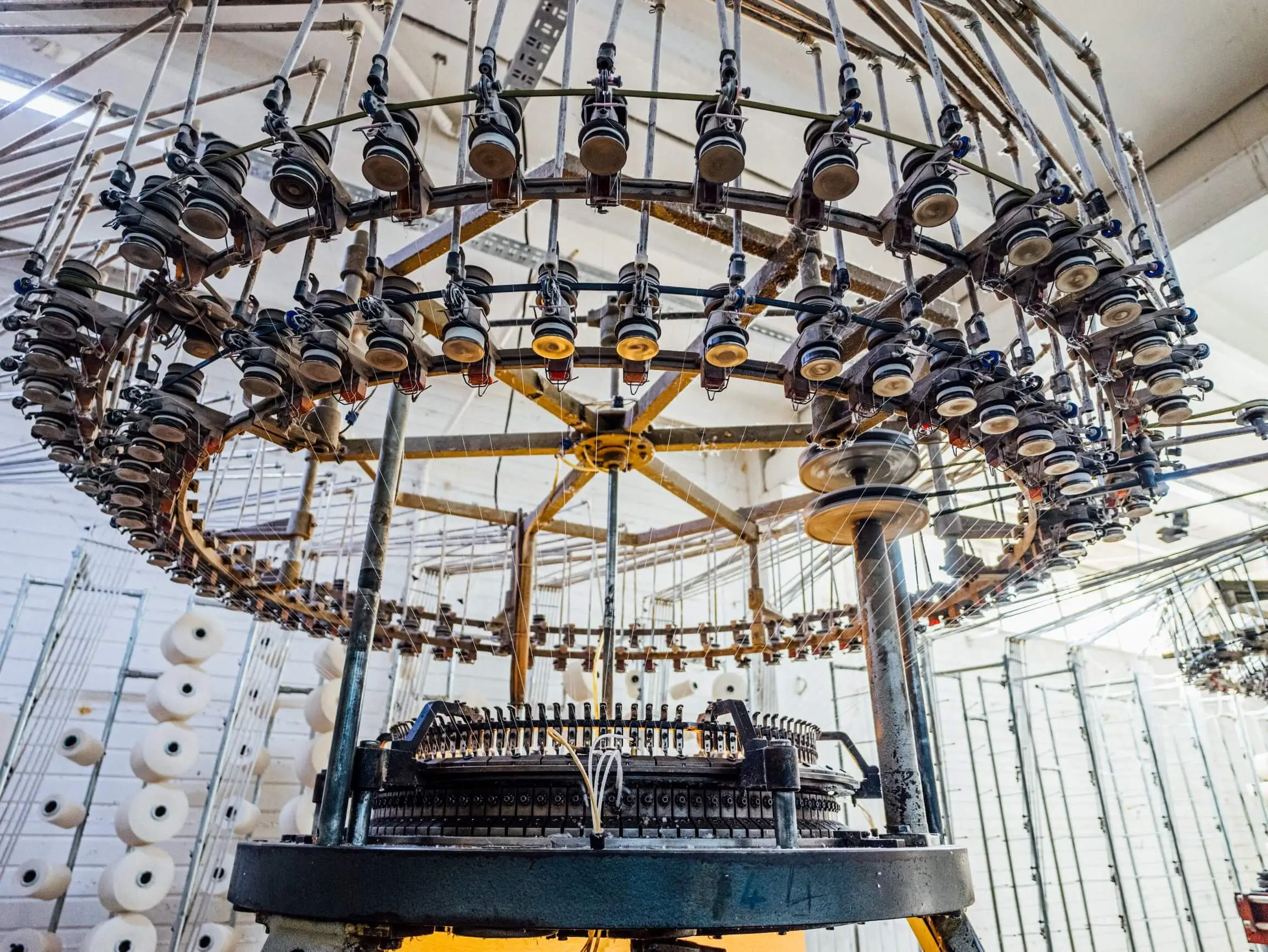

KNITTING

The knitting starts in accordance with the determined weight and quality. The yarn is fixed, needles are placed in the cartridge. The needles do the knitting work together and knitting process is completed in this way.

PAINTING

Afterwards, the finished knitted goods are dyed in the desired colors with the automation system that performs dyeing and finishing and become cloth batches.

CUT

The cloth batch is then cut in the cutting machine in accordance with the dimensions.

PLANTING

The cut goods are separated size by size and the sewing is started.

QUALITY

The finished products go to the quality stage.

PACKAGING

After the quality control, the products are packed size by size and color by color.

SHIPMENT

After the packaging stage, the products are packed in parcels and the barcode is affixed depending on the size and ready for shipment before the deadline.

Our company has dobby and jacquard towel machines and cloth weaving machines. Terry weaving products include towel, bathrobe and door mat groups. Our cloth weaving is generally for hotel and home textiles.

With 45 circular knitting machines, our company has a production capacity of 3000 tons. We provide fitted sheet, pique and knitted towelsthanks to our machines that produce fabric in desired weight.